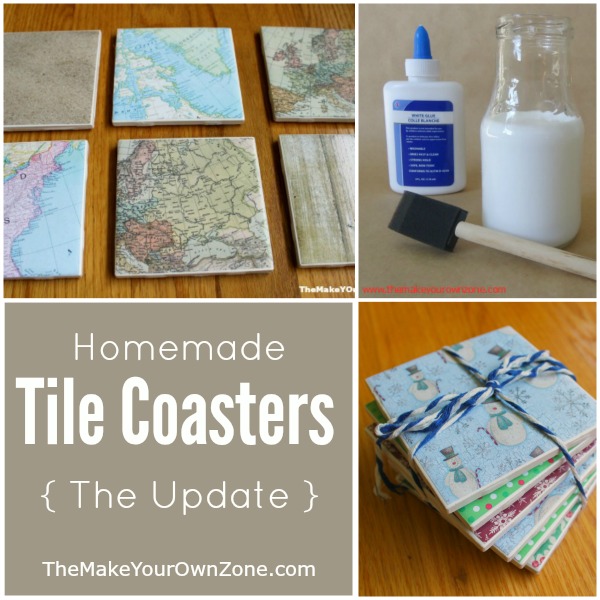

Homemade Tile Coasters: The Update

Three years have gone by since I first wrote about my DIY tile coasters. It was a cute and simple project using ceramic tiles from the home improvement store and scrapbook paper. I’ve been using my coasters (almost every day!) since that time and they’ve worked great.

In fact I like them so much, that I recently made a couple more sets of coasters and decided to do this quick little update.

Since I first wrote about this project, I’ve been asked the same question several times by those who made these coasters but then report that hot beverages stick to the coasters and they would like to know what went wrong. And unfortunately because this problem has never happened to me, I don’t really know what went wrong . . . and I wish I had a better answer than that.

The best I can do is to suggest variables in the materials used to see if perhaps they used something different from me that gave different results. Here are the materials I use:

Homemade Mod Podge: Every time I’ve made this project I’ve used my homemade Mod Podge that’s a simple mix of equal parts white glue and water. It’s always worked perfectly for these coasters and is very cheap to make too. For those who report stickiness, an option would be to not use store bought Mod Podge and just try this homemade mixture instead which I think is a bit thinner than the store bought varieties.

Sealer: I’m still using up the first can of sealer I bought for this project which is Aleene’s Spray Acrylic Sealer in Gloss Finish. I just do one light coat of the sealer on my coasters. I always wonder if other sealers might be giving different results when people report stickiness. Again, I don’t really know if the sealer is the problem, but I CAN say that the Aleene’s brand (which I purchased at Michaels Craft Store) has performed very well for me.

Scrapbook Paper: Each time I’ve made these coasters I’ve used scrapbook paper which is a heavier type of paper. Someday I’d like to give this a try with glossy photos, or something printed on computer paper, but that’s still on my to-do list! The paper is probably not part of the stickiness problem, but I thought I would add the type of paper I’ve used to the list of variables just in case.

Two More New Sets of Coasters

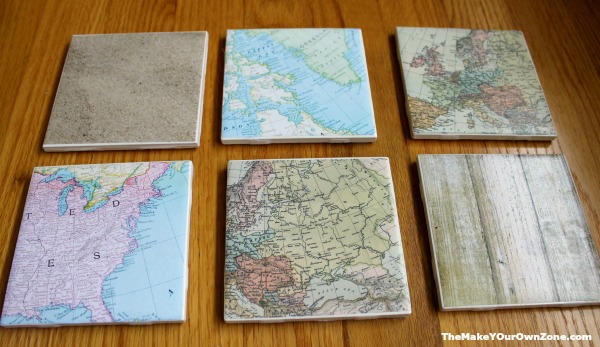

In the last few months I’ve made a couple more sets of these coasters. They’re kind of addicting to make because they go together pretty quickly and there are so many colorful scrapbook paper designs to choose from.

One set of coasters was for my son to use in his new apartment. This gave me a chance to look for some “manly” scrapbook papers which was something a little different. We both really liked the ones that looked like maps.

Last December I bought some holiday scrapbook papers with the intention of making a set of coasters for the Christmas season. And then things got busy as things so often do around Christmas and I never got around to it. Finally in February I made my Christmas coasters. I told myself instead of being behind, I was just super duper ahead of the game for NEXT Christmas. 🙂

You can read the complete instructions for making these tile coasters on the original post here: DIY Tile Coasters.

A very brief set of instructions here is to put a coat of Mod Podge on your tile, then lay on your cut piece of scrapbook paper, cover with another coat of Mod Podge, and then let it dry. Once dry, spray with a light coat of sealer and let that dry. Finish by sticking some felt on the back of your coasters.

So . . . keep me out of the craft store. Every time I see scrapbook papers, I want to make more coasters!

Using automotive spray sealer will solve the sticking with hot beverages issue.

I did placemats with photos, mod lodge and sealer. You have to photocopy the photo first you want to keep it. It took several coats mod lodge and several of the sealer. After a few years wear and tear the photos starting lifting up.

I can help with what went wrong with the tiles when something hot is put on them. They need to be sprayed or brushed with a finish that is used on car parts. It is still clear, but heat resistant. Can be googled. I asked someone at a craft fair and that is what they told me they used on their coasters so they can put hot coffee cups on them.

Thank YOU! That will come in handy this holiday season when making my DIY Coasters for co-workers and neighbor gifts!!

where can we find such materials in the market?

I buy my ceramic tiles at big box home improvement stores such as Home Depot or Lowes. I buy the other supplies in craft stores.

I just picked up a big box of tiles at a rummage sale. Great deal.

That sounds like an awesome bargain! You never know what you might find when you shop rummage/garage sales 🙂

Could you use fabric?

Yes, I think you could probably use fabric Vivi. As long as it sticks to the tile well with the Mod Podge, and if you give it a coat of sealer, I think it should work!

I wonder if people are using hot water or cold water to mix the glue and water? That can change the properties and make sticky results? Also wonder how long the glue lasts in a glass jar?

I have had this mixture in my glass jar for a couple years now and it is still perfectly fine. I don’t think it will go bad either, being just glue and water. And I never considered that water temperature could be a variable in this homemade mod podge. That’s something to consider!

It is quite possible that humidity is a factor. I was given some salt clay Christmas ornaments that we’re painted, then sealed. They never completey dried and actually got stckier with time. I live in Florida, so humidity is a factor most of the year! I try to let Mod Podge dry for a longer time prior to sealing it. Good luck!